Since we used Jerry's frame rails, we'll have to make our own skid plate. Rather than making it out of aluminum, I decided to make one out of HDPE plastic. The reason was because the plastic will be much easier to conform than aluminum, it should also be able provide more protection all around.

I ordered up a 2ftx2ft section of 1/4" thick HPDE plastic, was even able to find it in green!

Man! that thing is huge, it's about big enough to cover a football field! We'll make a cardboard template later and get to work. First, I want to get a 2 piece clutch cover with a hinson cover on it before doing any heat forming/cutting.

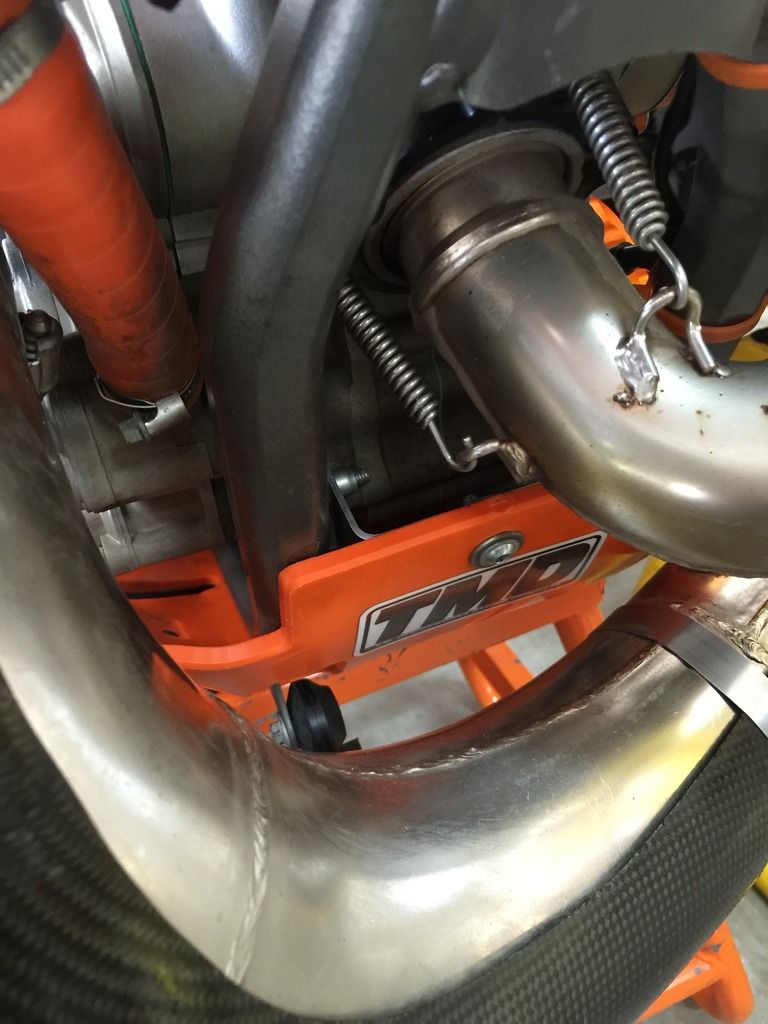

Seeing my dad's KTM, it gave us an idea. I wanted a skid plate similar to the TM Designworks one.

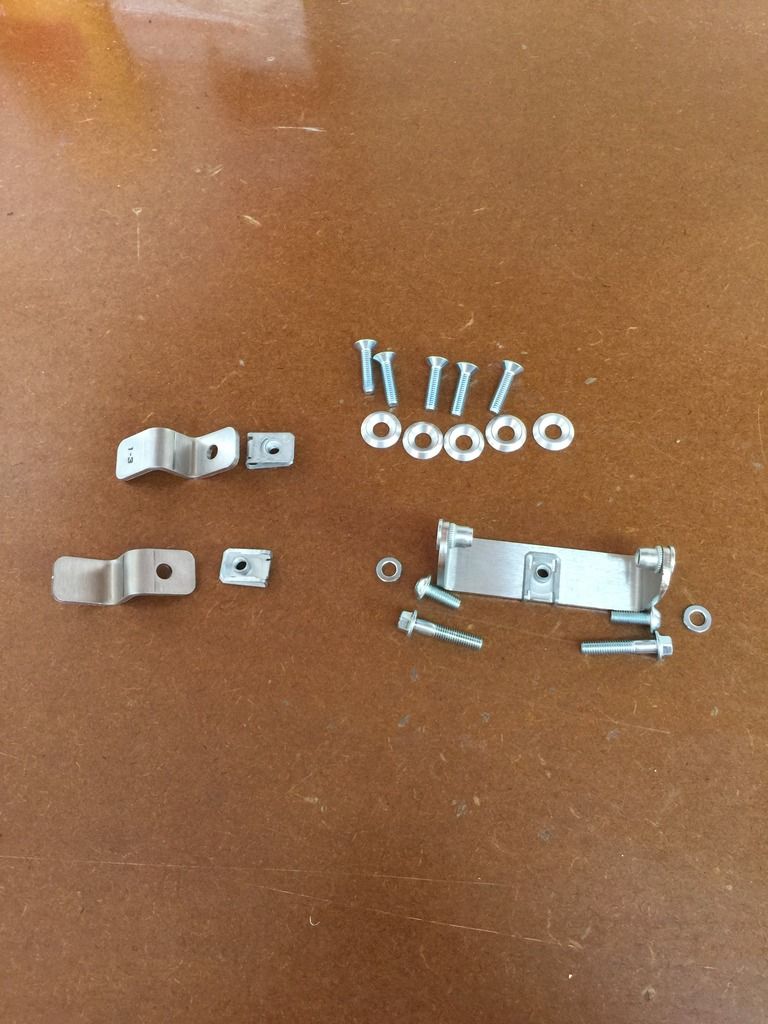

We determined that we would be able to use the KTM's mounting z brackets and u bracket, as well as the mounting hardware for the ktm mounts and kx450 crossmember. A simple call to TM Designworks and we were able to make it happen. A big thanks to Jerry @ TM Designworks for hooking us up. We will have to shim the center mounting bracket with 1 washer on each side, but everything else works perfectly. I did have to stop by the hardware store and pickup 2 longer bolts for that plate, because my mounting tabs are a lot thicker than the ktm's. I wasn't able to find the allen head cap style, but found miniature hex head ones (8mm head) that are the same width on the head size. Should look great when it is installed.

As I mentioned earlier, we replaced the fuel plate barb with a new, bigger one. It was then welded. The headstay mount was welded with very thick and beefy welds, I told the welder to go nuts on it. The head stay mounts were cut down about 1/4" in the back, and 1/8" in the front. The back plates were cut to give room to remove the bolts. The front part was cut an 1/8" to match a little bit nicer. We now have a fully disassemble-able head stay! I love the thickness, I think it is absolutely vital to have a strong head stay.

Remember I said that there was going to be bling?

. This is just the beginning. Radiator stickers.

I was also able to get an awesome deal on a Pro Moto Billet Kickstand. Score! These are absolutely necessary for us trail riders! Awesome piece, I have one on every bike.

..and this brings us to where we are currently on the build. I am waiting for a 2 piece clutch cover so that we may begin fabricating the skid plate. I plan to have a decompression valve installed in the head. I will also hopefully be getting with Roostius on buying one of his extended clutch arms. We have a little more ways to go. Everything beyond rebuilding the engine is small. Graphics, plastics, possibly wheels, etc. I'm really excited and happy with how it has turned out so far!