Hey all. A few more updates from this last week of getting to work on the 500 a bit...

So I had originally bought some Applied 20mm KXF clamps for the bike before I had the A kit. When I got ahold of the AKit it came with some used PC clamps. they were pretty blasted from sand and anodizing was worn off a good bit, so I sent them to get stripped and re-ano'd. Well, turns out, there were a ton of hairline cracks in the bottom clamp. So those had to end up being scrapped unfortunately.

I had that HPSD adapter welded onto the bottom of my Applied clamps by this point, so I ended up sending them back to Applied to hopefully be able to get them bored out to A Kit hole dimensions.

They were barely able to do it (way the clamp bolts are close to the hole) but pulled it off, then sent to get anodized. Got them back and have been battling ever since with the fork fitment for some reason. Both clamps by themselves slide over the tubes fine, but when going thru the stem and both clamps, it takes some forcing to get the forks to slide thru the top clamps. Knew something was up here. Thought they may have misplaced a clamp and sent back a different offset mix-matched or something. Turns out, there was a little weld on the bottom of the lower clamp when i put the HPSD adapter on, and the guy working there at the time didnt check to make sure the clamp was flat in the mill before boring. So it added another angle to the offset basically, just enough to mess things up when you tried to put it thru the top.

Figured out the issue, Applied was awesome dealing with me, super good guys. Re-made me a lower clamp and we did a different take on the HPSD design as well, pretty trick. Bolt on design vs weld on so saved me a trip to the welder.

Now after another HPSD top bracket revision, forks fit up perfectly, new bottom clamp, and HPSD is fitting perfectly with enough free play on both ends.

The fork tubes are weird sizes at the flange near the dust seal. Had to have Kevin @ Tamer Holeshot Devices send me a handful of tube clamps to try and test fitment. Turns out one off an older KTM fits up pretty well. Test fitment on the stock fork guards just for kicks. I'll be making some out of carbon fiber for this project.

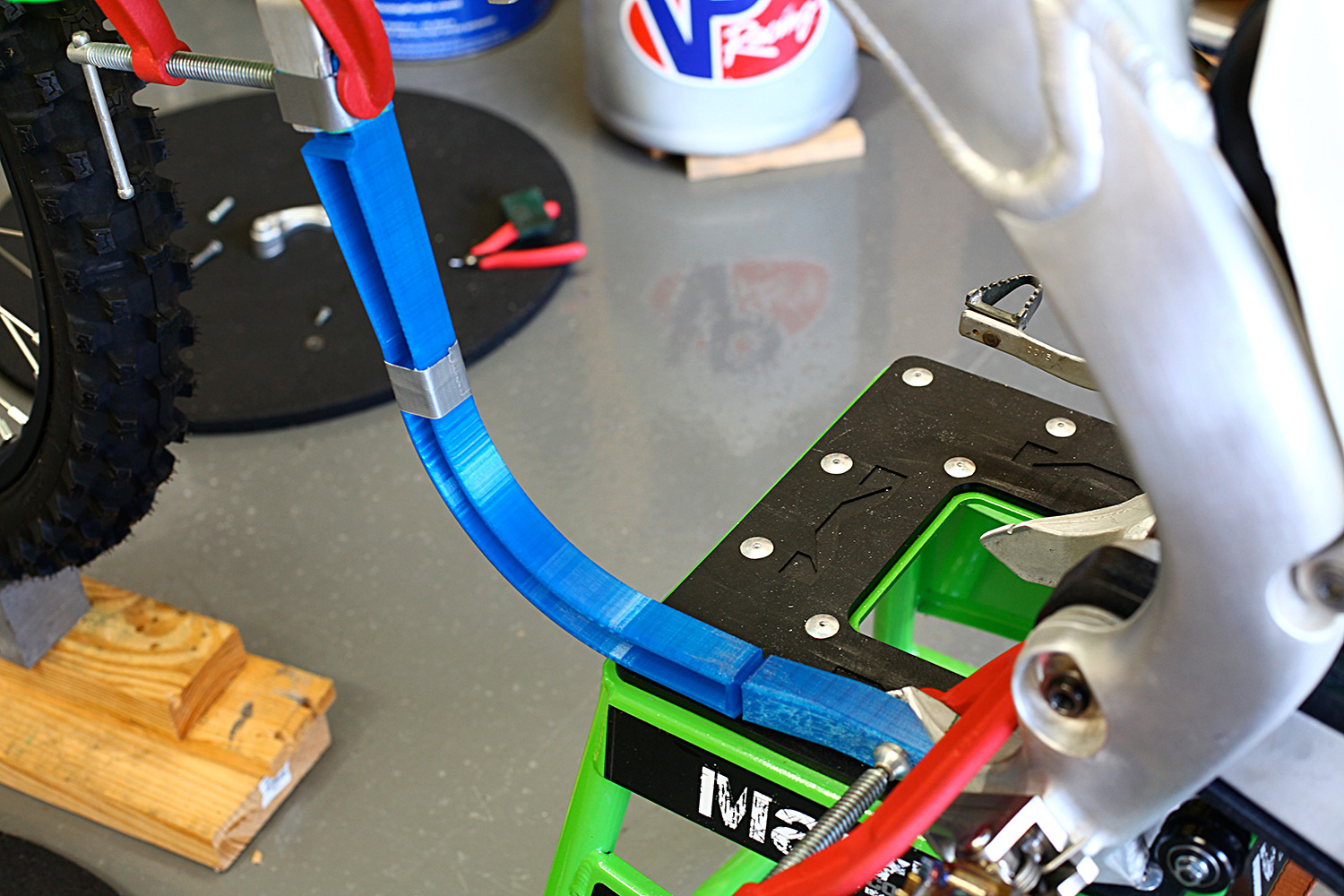

Looks like my measurements on the frame rails turned out to be spot on. maybe .008" off but that is PLENTY close enough for this. You can see in the overhead shot where i put the bend in to reach out to the different width near the swingarm receptacles.

This is good to go, going to put in the weight relief recesses like I did on the Yoke on the inside of the rails, then get this thing sent off to get CNC'd. I'll have to wait till i get the frame rails welded in, before I can make the new top and bottom engine mounts though, as all 4 are different 'widths' to mate up to the engine cases perfectly.

Still working on getting the front and rear brake caliper adapters modeled up, as its a pretty fair amount of work, but getting closer.

Thought that just running the brembo rear caliper and using the stock nissin rear master cylinder was a bit half assed, but the issue is the bolt pattern spacing on the two master cylinders is different.

Shaved the stock mount off the frame, measured up a new one that fits the brembo, and test printed the adapter, fits perfectly. Should be pretty easy to tack on, then not use any filler on the face, and smooth it out so it looks stock.

Playing around with an idea for the front cable stay, rather than the ghetto looking white plastic loop that comes on the bike.

Made this up real quick, Wanted a cable stay that mimic'd the lines of the front number plate, sort of like how the KTM design is done. I got close on this initial one but it needs to standoff a bit more from the clamps. Should be an easy revision. I also put a recess on the back of the part so it snaps in tight fitment to the triple clamp bolt standoff, this keeps it from twisting.

Got a few new parts in. Lightspeed CF chain guide, and Yoshimura factory edition axle blocks in matte black.

And a cool Yoshimura stem nut as well in matte black.

CRF Killswitch

Probably my most adventurous aspect of this bike may be the subframe. Wanting to do a carbon fiber design, and use the air filter style off a KTM since its so amazing and minimal.

Got in a '14 125SX airbox, and chopped out the filter/intake/boot. Plans are to mesh this design in with the CF subframe so its 1 piece, and using a KTM rubber boot design as well.

Thanks for the continued support and I'll be posting more updates as soon as I can.

Taylor